Some Of Kawneer Spandrel Panel Metal Spandrel

Table of ContentsInsulated Spandrel Panel Detail - TruthsGable Spandrel Panel Can Be Fun For EveryoneGable Spandrel Panel Things To Know Before You BuyThings about Insulated Spandrel Panel

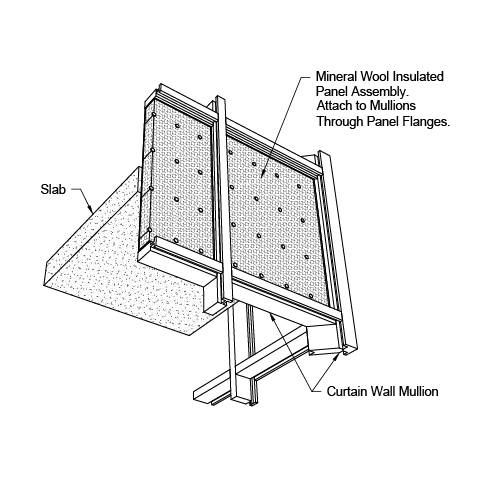

The systems ought to be entirely put together in a manufacturing facility and delivered to the site for setup on the building. The units are put on the floorings, packed in pet crates, making use of the tower crane and reduced right into place utilizing a smaller crane or lift owned by the glazing professional. The mullion measurements tend to be somewhat bigger than a stick system because of their open section as compared to the tube form of a typical stick curtain wall area.

Devices can be assembled in a factory while the architectural framework of the building is being created. Where stick systems call for multiple steps to put up as well as secure the wall surface, unitized wall surfaces arrive on the website totally assembled enabling the floors to be enclosed extra quickly. Unitized systems also call for much less space on website for format hence offering a benefit for metropolitan websites with room restrictions.

The interlocking upright mullions will normally have 2 interlocking legs. One leg will remain in the aircraft simply behind the glazing pocket and also the other at the interior face of the mullions. The interlocking leg in the plane of the glazing pocket will certainly be secured by gaskets as well as is the main line of protection against water and air seepage.

Solutions whose attaching legs lock also jeopardize the capacity of the system to suit movement. Some unitized layouts are sensitive to little irregularities in the spacing of nearby components; for instance, if the module joints are slightly out of tolerance, gaskets may not be correctly pressed as well as moisture security might experience.

Things about Kawneer Spandrel Panel Metal Spandrel

The four-way crossway refers to the location where 4 nearby devices meet. This is where area labor have to secure between surrounding systems to achieve a climate limited wall surface. The interlacing legs of the straight mullions are the most critical interface of a unitized system. Water that infiltrates the interlocking upright mullions drains to the interlocking horizontals that must collect and also divert this water to the outside.

These upstanding legs have gaskets that secure versus the walls of the lower straight. Some designs offer one good leg that provides one line of protection versus air and also water infiltration. Much more durable systems will certainly offer 2 upstanding legs with gaskets on both legs. A splice plate or silicone flashing that is set up at the top of both nearby units as they are erected on the structure is typically needed.

The stack joint is the horizontal joint where systems from adjacent floors meet. Positioning the pile joint at the sill of the vision glass (commonly 30" above the floor) will lessen the dimension of the upright mullions. This positioning makes use of the back span of the mullion above the anchoring factor at the slab to neutralize the deflection of the mullion listed below the piece.

While 2 tale spans are viable, the weight of the system is doubled which might call for raised architectural ability to suit the increased load. Wind tons bracing ought to be integrated at the single period height to stay clear of boosting the upright mullion dimension to accommodate the raised Recommended Reading period. Steel can be contributed to a unitized system to boost its extending capability.

The Definitive Guide for Kawneer Spandrel Panel Metal Spandrel

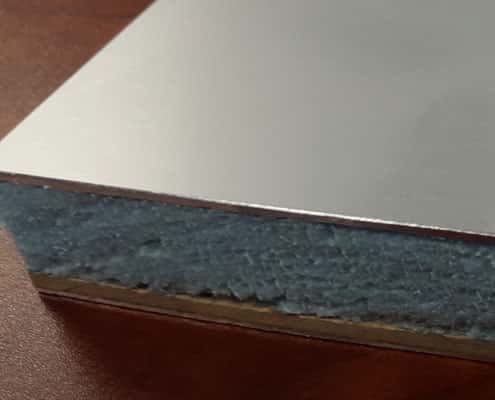

Large units may also raise transportation expenses from the manufacturing facility to the site as well as erection costs of placing the devices on the structure - nhbc spandrel panels. Thermally broken unitized systems are offered, using similar innovation as that utilized in stick drape wall surface systems. The life span of also the most sturdy drape wall surface may be much shorter than that of resilient surrounding wall claddings such as rock or block masonry.

The life span expectations of elements that are mated with the drape wall surface into a setting up need to match the life span expectations of the curtain wall itself. Need sturdy blinking products, non-corroding accessory equipment and fasteners, and wetness immune materials in regions subject to wetting. Laboratory testing: For projects with a substantial quantity of custom drape wall, need research laboratory screening of a mock-up curtain wall prior to completing project store drawings.

Specify that laboratory tests are to be conducted at an AAMA Accredited Laboratory center. Field Mock-up: For all curtain walls, stock or custom-made, need building and also testing of an area mock-up representative of the wall/window assembly. This is ideal scheduled before the release of store illustrations for window manufacturing, so that there is an opportunity to make layout adjustments based upon the test efficiency of the area mock-up.

Area testing of drape walls: Require the area testing of drape wall surfaces for air seepage and also water penetration resistance, for quality control of curtain wall construction and also installation. insulated spandrel panel detail. Need several tests with the first test on first installations and also later examinations at insulation behind spandrel glass details around 35%, 70% and at last conclusion to capture issues early as well as to verify ongoing craftsmanship quality.

The smart Trick of Fire Rated Spandrel Panel That Nobody is Discussing

Shop drawing control: Call for drape wall surface installation spandrel panel design store drawings showing all adjacent building as well as associated job, consisting of flashings, add-ons, indoor coatings, and showing sequencing of the job. Drape wall surface systems, specifically unitized systems, call for experience for the structure developer, the maker, the maker, as well as the installer. For all yet the most basic of systems, the developer ought to think about engaging an outside specialist, if such know-how is not offered on the personnel.

The information connected with this area of the BEDG on the WBDG were created by committee and are meant only as a way to illustrate general layout as well as building concepts only. Proper use and also application of the principles highlighted in these details will differ based on efficiency considerations and ecological conditions special to each project and also, therefore, do not represent the final point of view or recommendation of the author of each section or the board participants in charge of the growth of the WBDG.